Hi All,

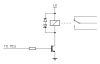

I am working on a maze for my research lab at school, hopefully replacing a large opto isolator (picture attached) with a smaller one. I found one that might work but I'm not sure. It is connected to a solenoid.

https://www.sparkfun.com/products/9118

The large one is working it is too big. The controllers run on 5v and a 12v battery powers the solenoid

The specs of the solenoid : 12 V 540 mA 6.5W

If I omitted something or got something wrong, sorry. This is over my head. Trying to figure it out. If you could tell me if that small one would work or what I'd need I'd appreciate it!

Thanks in Advance to All

I am working on a maze for my research lab at school, hopefully replacing a large opto isolator (picture attached) with a smaller one. I found one that might work but I'm not sure. It is connected to a solenoid.

https://www.sparkfun.com/products/9118

The large one is working it is too big. The controllers run on 5v and a 12v battery powers the solenoid

The specs of the solenoid : 12 V 540 mA 6.5W

If I omitted something or got something wrong, sorry. This is over my head. Trying to figure it out. If you could tell me if that small one would work or what I'd need I'd appreciate it!

Thanks in Advance to All