LKO Railroad

- Aug 9, 2013

- 43

- Joined

- Aug 9, 2013

- Messages

- 43

I am building a model railroad. The track requires a constant 15V DC on the rails. A radio receiver module within the locomotive receives commands from a handheld controller. The module then regulates the 15V DC to the motor to control locomotive speed and direction. A typical locomotive draws 250-500 mA. There likely will never be more than 8-10 locomotives in operation simultaneously across the entire layout.

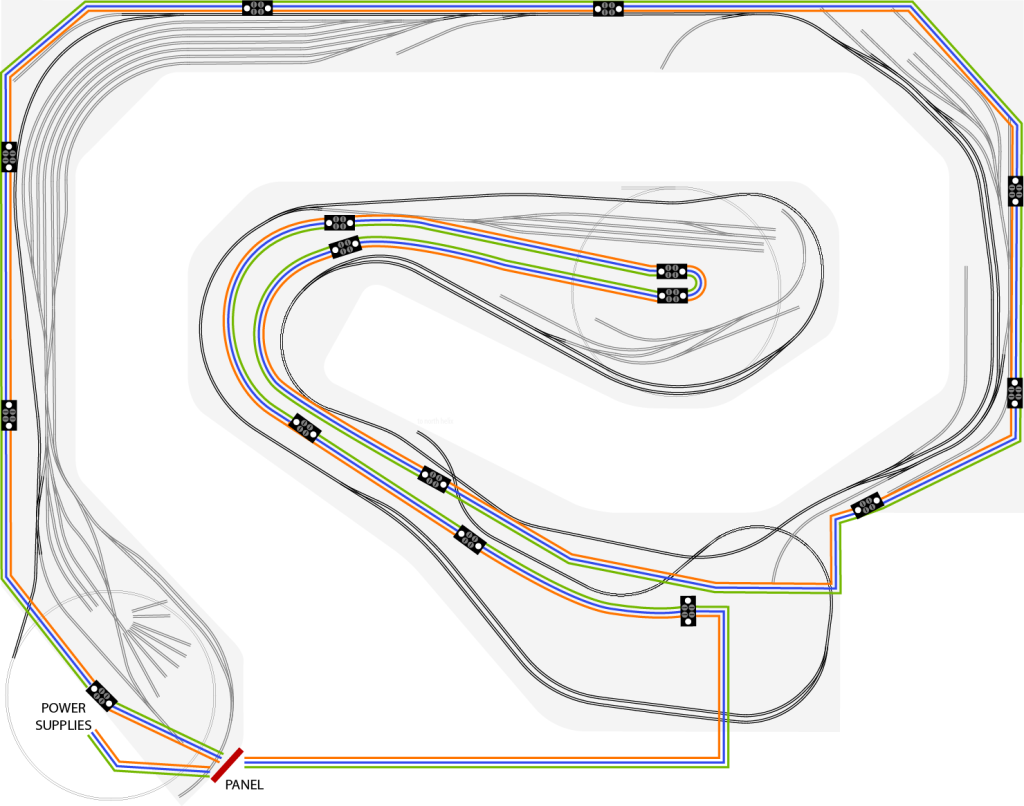

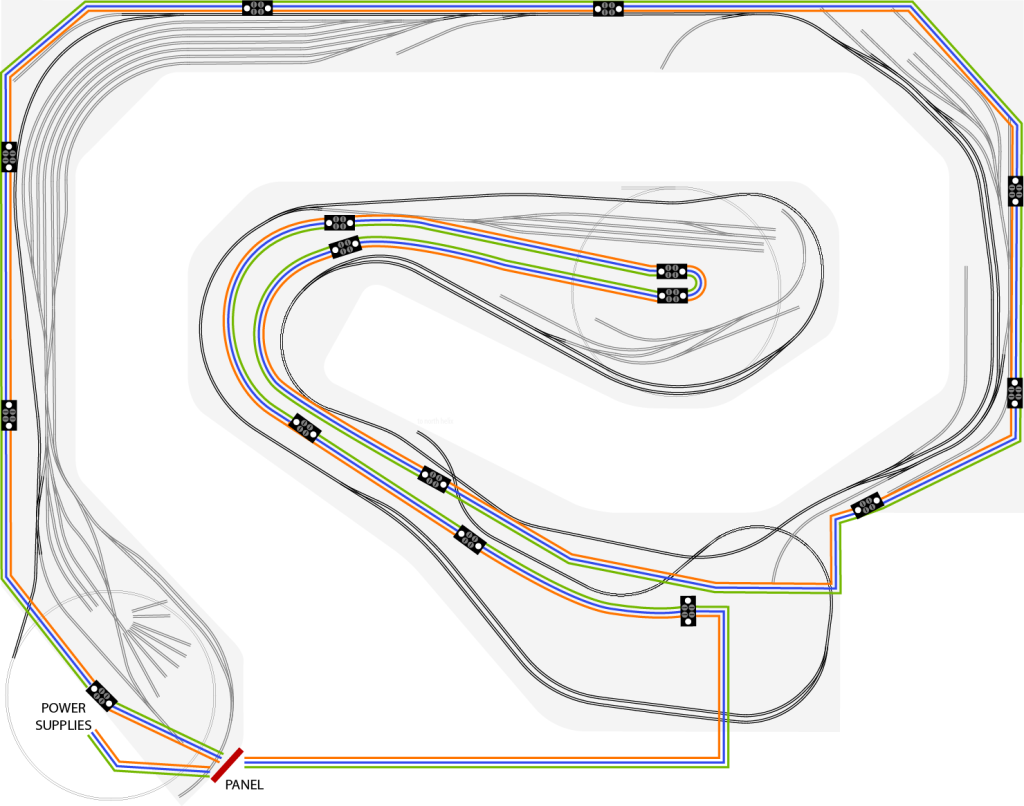

I am using a Mean Well 15V 7A switching power supply to power the rails. The power supply is connected to an ammeter about 6 feet away. From the ammeter a loop of bus wire (orange) goes all the way around the layout. All wire is 12AWG solid THHN. The overall length of the bus around the layout is approximately 140 feet. A full description is here.

There are two addition power supplies and buses in the same fashion. One for controls (blue), the other for accessories (green). Essentially there are 3 copies of the power bus on the layout.

I have been informed that running the bus in a loop may be a problem. None of the gang I hang with knows anything more about electricity than I so I come hat in hand to you guys.

Will my DC bus loops be a problem? Thank you in advance.

I am using a Mean Well 15V 7A switching power supply to power the rails. The power supply is connected to an ammeter about 6 feet away. From the ammeter a loop of bus wire (orange) goes all the way around the layout. All wire is 12AWG solid THHN. The overall length of the bus around the layout is approximately 140 feet. A full description is here.

There are two addition power supplies and buses in the same fashion. One for controls (blue), the other for accessories (green). Essentially there are 3 copies of the power bus on the layout.

I have been informed that running the bus in a loop may be a problem. None of the gang I hang with knows anything more about electricity than I so I come hat in hand to you guys.

Will my DC bus loops be a problem? Thank you in advance.