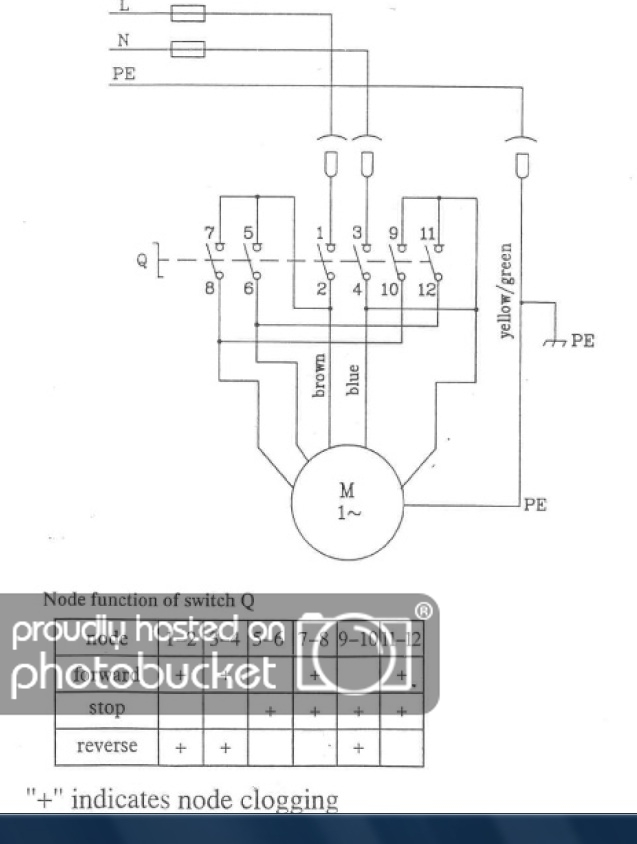

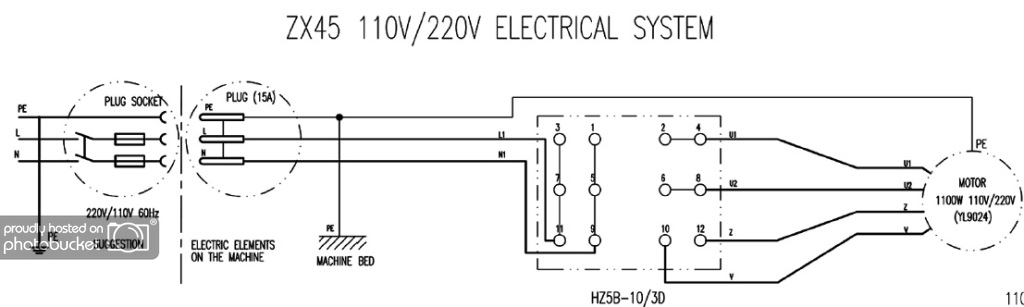

I have a bad switch on my machine and was given this new switch by a dealer of these milling machines, but its very different looking in the way its hooked up than the one on my machine

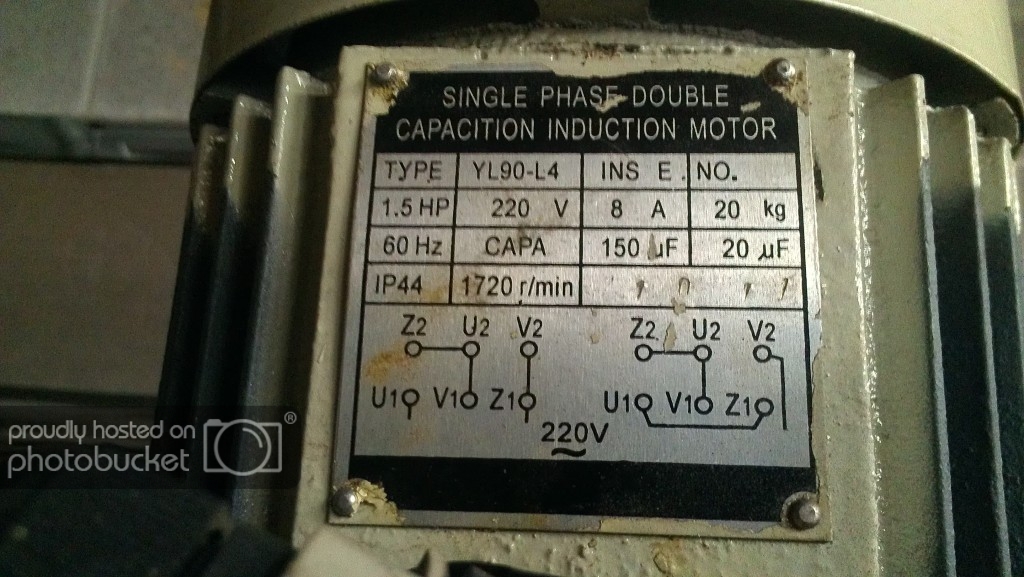

Machine is a 220 volt 1-1/2 hp milling machine (for milling down metals)

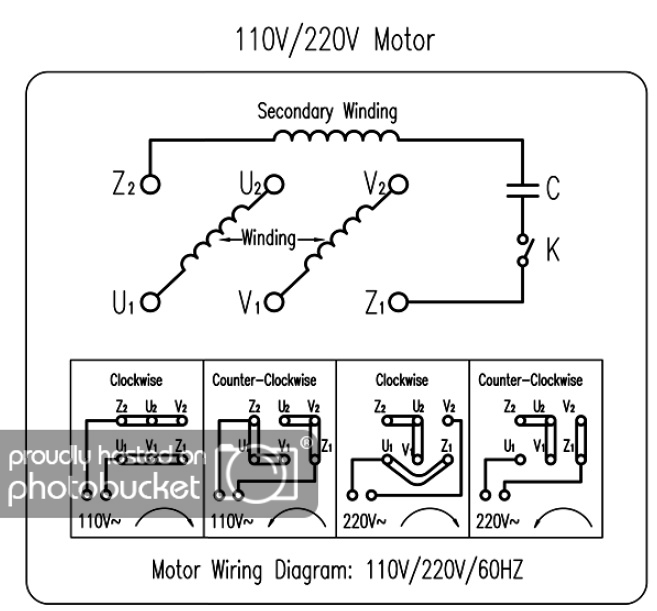

What I need to know is where to put the wires on the switch to make it work

Machine needs to go in: Forward - Stop - Reverse

I have the 2 power wires that need to be hooked into switch the ones coming from the outlet (2 hot wires)

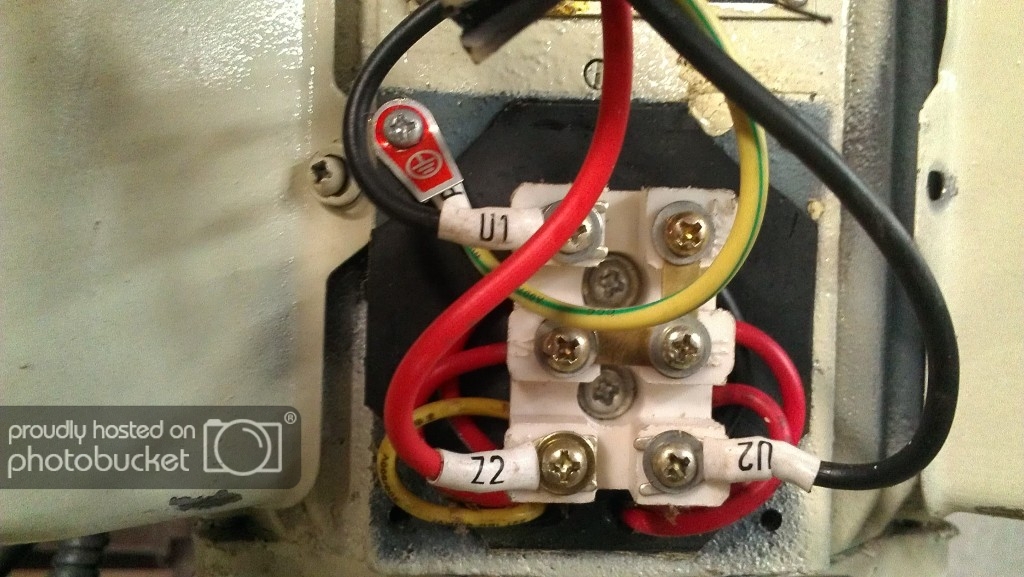

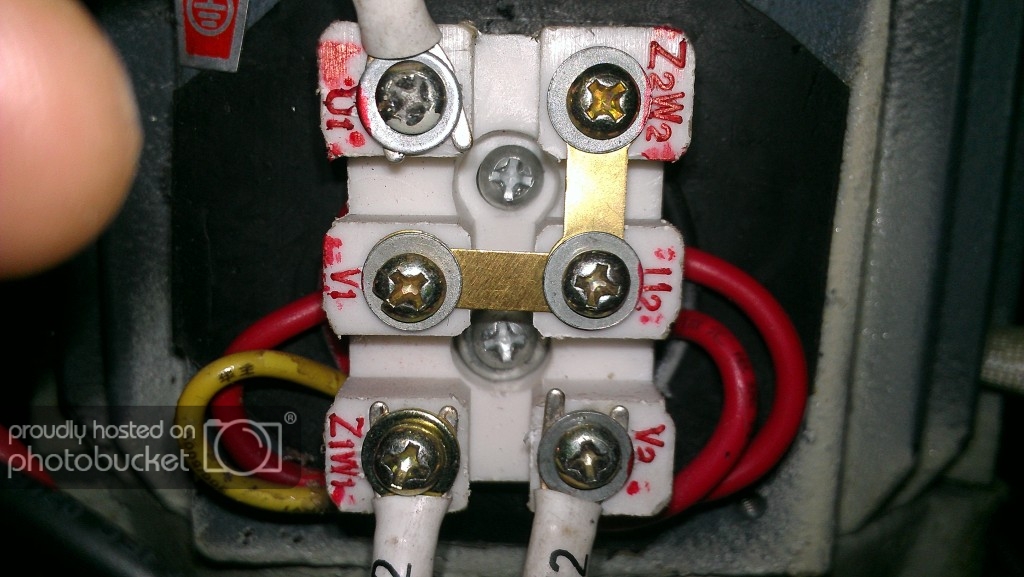

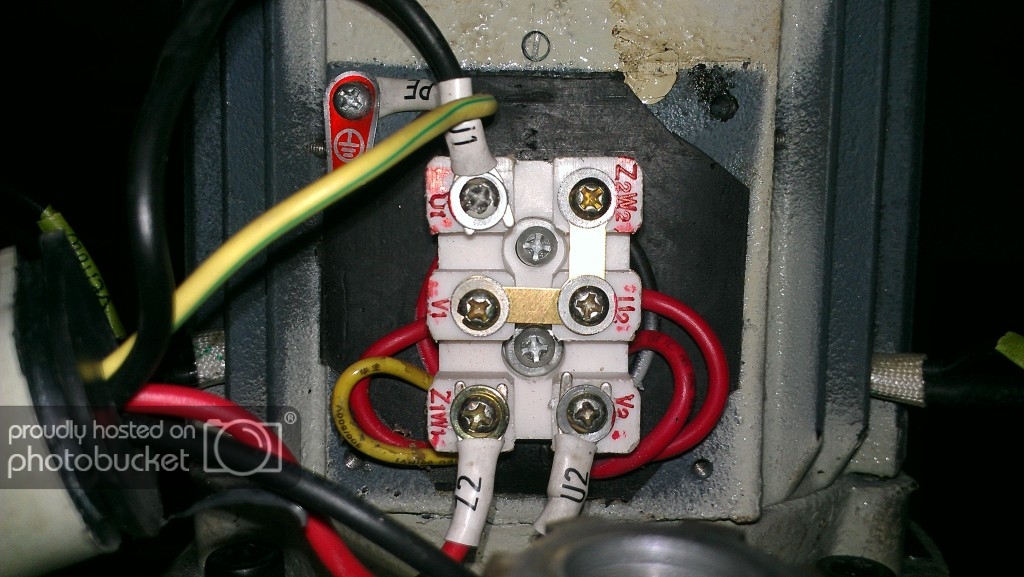

Then out of the switch I have 3 wires going straight to motor, they are:

Black wire labeled - U1

Black wire labeled - U2

Red wire labeled - Z2 (which I am guess make the motor reverse)

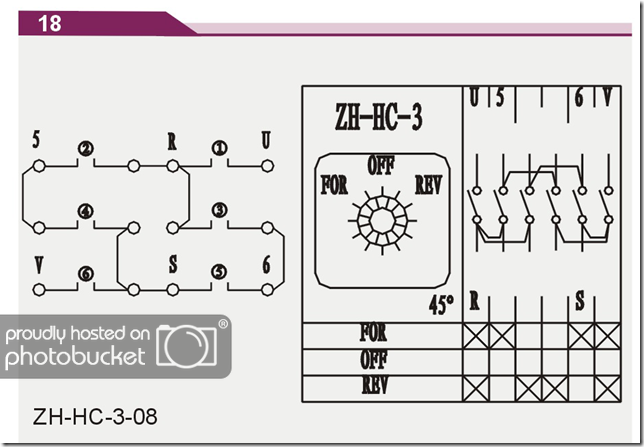

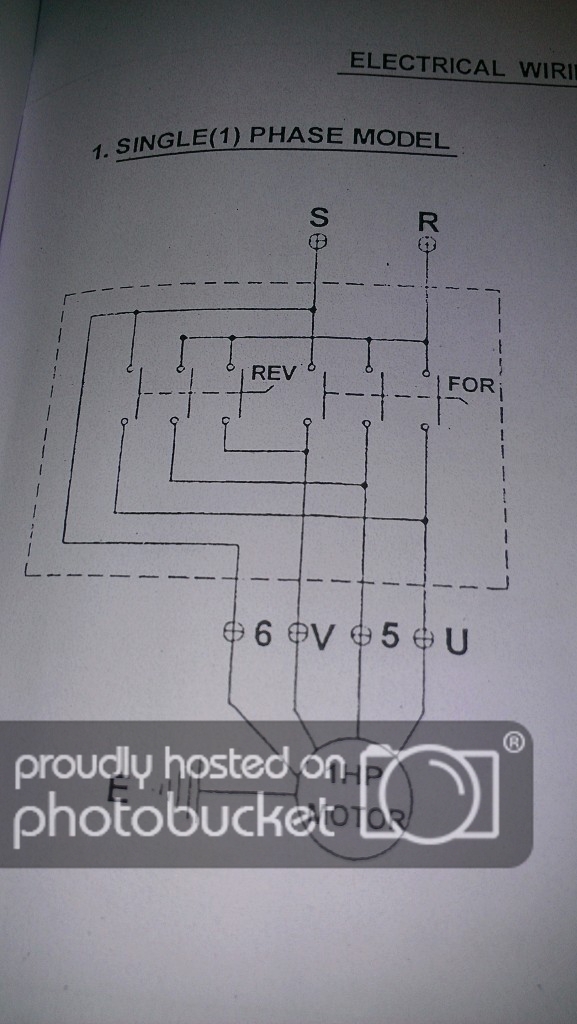

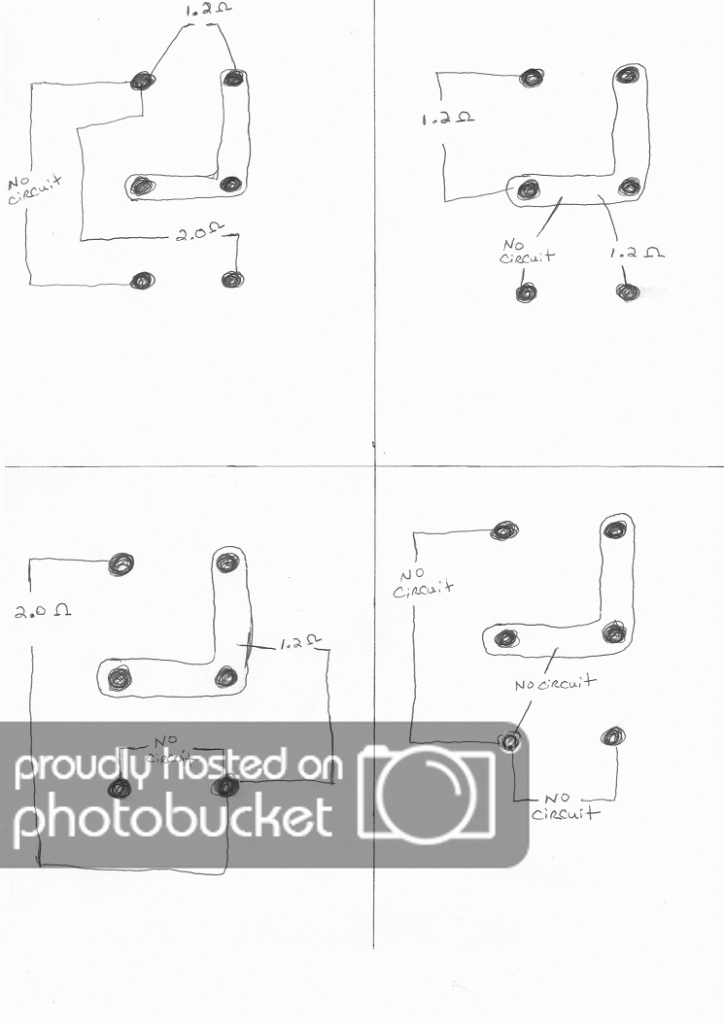

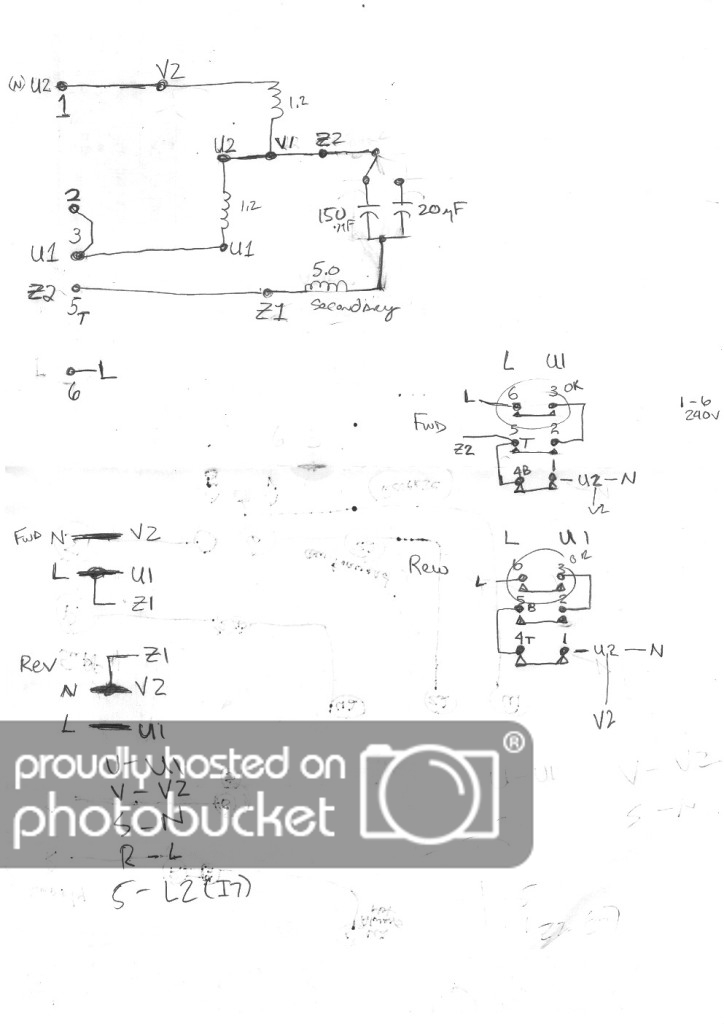

Picture of schematic of switch that needs to be put in

Machine is a 220 volt 1-1/2 hp milling machine (for milling down metals)

What I need to know is where to put the wires on the switch to make it work

Machine needs to go in: Forward - Stop - Reverse

I have the 2 power wires that need to be hooked into switch the ones coming from the outlet (2 hot wires)

Then out of the switch I have 3 wires going straight to motor, they are:

Black wire labeled - U1

Black wire labeled - U2

Red wire labeled - Z2 (which I am guess make the motor reverse)

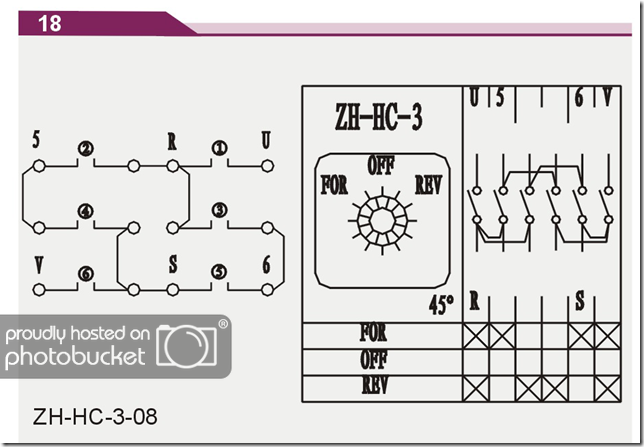

Picture of schematic of switch that needs to be put in