hotmaildotcom1

- Apr 27, 2017

- 11

- Joined

- Apr 27, 2017

- Messages

- 11

First I would just like to state that this isn't one of those "please help me I desperately need you to fix this for me" posts. This is my first post on this forum and I am just trying to fix this monitor in my spare time as it recently stopped working. Probably picking up a Craigslist replacement here in the near future so this is definitely just a post because I am interested in the the issue.

Alright with that said I am working on a LG Flatron L1751S-BN monitor that recently developed a pretty interesting little quirk. The power light will not come on and it simply won't turn on. That is until it warms up and decides that it wants to work. Once it powers on it will keep going until it either goes into sleep mode or is turned off for about 5 minutes. This problem was originally circumnavigated by simply just going without it for five to ten minutes until it was good and ready. I disabled my screensaver and would just let the image run on it until it decided to wake up. It now goes an entire day without turning on though so it's pretty much unusable unless I'm working at my computer all day, in which case it might come on some of the way through it.

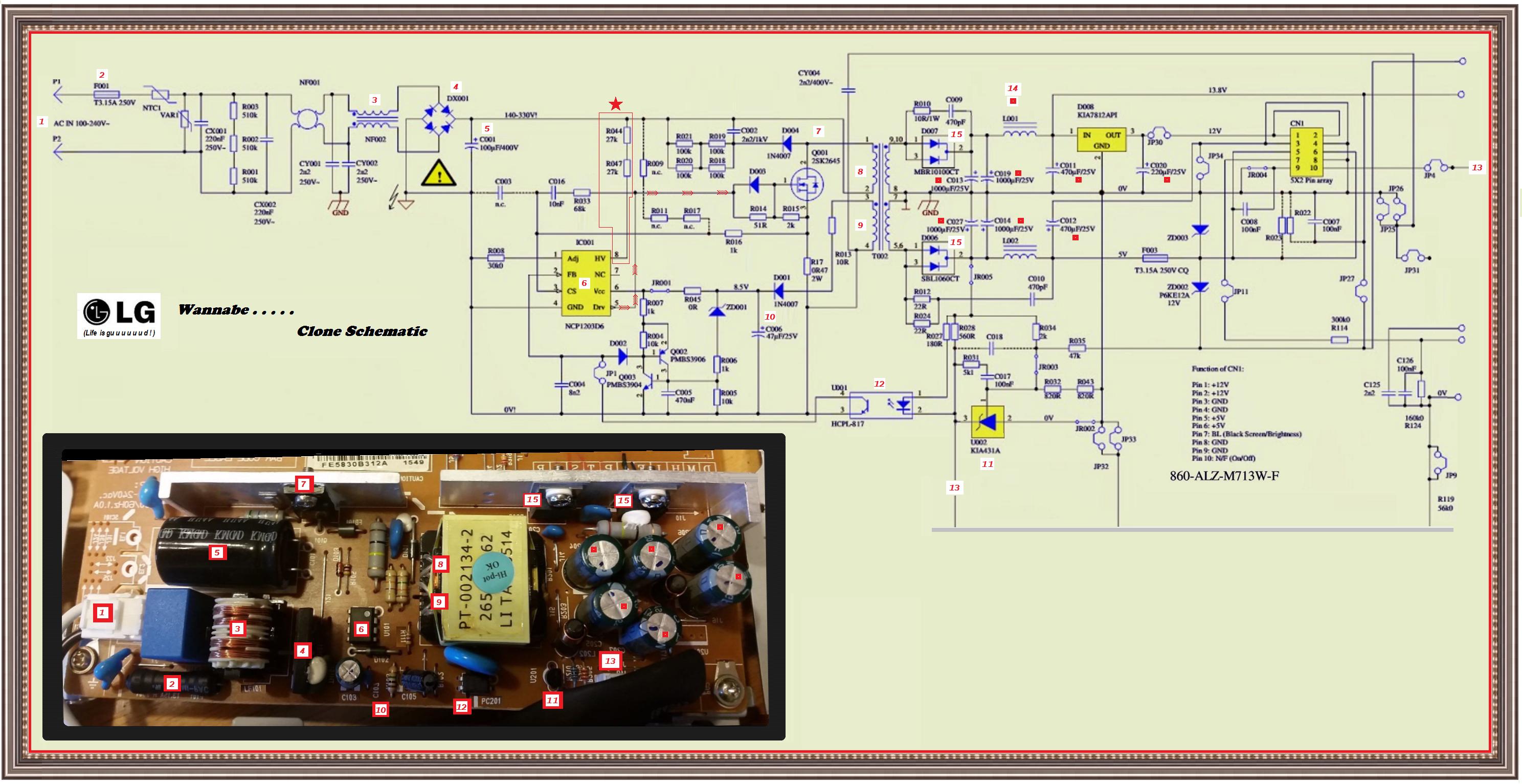

Into the troubleshooting. After many youtube videos and a great deal of forum reading I found that it was likely a capacitor issue. I tore into the thing after doing some safety related reading and determined that I couldn't see any capacitors that were really toasted or burst. Being careful not to make any contacts, I gave it some power in it's dissected state. I can here a very slight clicking noise coming from an internal component. It's the connector that powers the actual monitor after all of the fancy magic has been done on the actual printed circuit board [CircutBoard(1)].

I've included every picture I could of the current situation, but there's not much walking through the issue that I can do as I really don't know what's going on. CircutBoard(2) is a picture of the same component where the clicking is definitely coming from, just without the plug in it. When unplugged there is no clicking. CircutBoard(3) is an overview of the whole shebang, with the suspected component plugged in, but not in the frame.

Inspection of CircutBoard(6) shows some discoloration on the board near the two brass colored components at the top. However I imagine this is fine as those components are labeled "HS" which leads me to believe they are heat sinks, which would cause the board to be discolored there over time.

I have currently attributed the powering on to internal heat. During the winter whenever my house's heat would be on, and the vent is right above the monitor, the baby would start right up. Also the fact that it stays powered on when it finally does come on leads me to believe the heat coming from the screen keeps the dying component functioning.

Thank you again in advance for any input or even reading this. I appreciate any form of assistance, as once again I'm just trying to get into this to see what I can do with the product in its current state.

Alright with that said I am working on a LG Flatron L1751S-BN monitor that recently developed a pretty interesting little quirk. The power light will not come on and it simply won't turn on. That is until it warms up and decides that it wants to work. Once it powers on it will keep going until it either goes into sleep mode or is turned off for about 5 minutes. This problem was originally circumnavigated by simply just going without it for five to ten minutes until it was good and ready. I disabled my screensaver and would just let the image run on it until it decided to wake up. It now goes an entire day without turning on though so it's pretty much unusable unless I'm working at my computer all day, in which case it might come on some of the way through it.

Into the troubleshooting. After many youtube videos and a great deal of forum reading I found that it was likely a capacitor issue. I tore into the thing after doing some safety related reading and determined that I couldn't see any capacitors that were really toasted or burst. Being careful not to make any contacts, I gave it some power in it's dissected state. I can here a very slight clicking noise coming from an internal component. It's the connector that powers the actual monitor after all of the fancy magic has been done on the actual printed circuit board [CircutBoard(1)].

I've included every picture I could of the current situation, but there's not much walking through the issue that I can do as I really don't know what's going on. CircutBoard(2) is a picture of the same component where the clicking is definitely coming from, just without the plug in it. When unplugged there is no clicking. CircutBoard(3) is an overview of the whole shebang, with the suspected component plugged in, but not in the frame.

Inspection of CircutBoard(6) shows some discoloration on the board near the two brass colored components at the top. However I imagine this is fine as those components are labeled "HS" which leads me to believe they are heat sinks, which would cause the board to be discolored there over time.

I have currently attributed the powering on to internal heat. During the winter whenever my house's heat would be on, and the vent is right above the monitor, the baby would start right up. Also the fact that it stays powered on when it finally does come on leads me to believe the heat coming from the screen keeps the dying component functioning.

Thank you again in advance for any input or even reading this. I appreciate any form of assistance, as once again I'm just trying to get into this to see what I can do with the product in its current state.

Attachments

-

CircutBoard (1).jpg114.1 KB · Views: 101

CircutBoard (1).jpg114.1 KB · Views: 101 -

CircutBoard (2).jpg192.8 KB · Views: 125

CircutBoard (2).jpg192.8 KB · Views: 125 -

CircutBoard (3).jpg205.9 KB · Views: 91

CircutBoard (3).jpg205.9 KB · Views: 91 -

CircutBoard (4).jpg225.8 KB · Views: 123

CircutBoard (4).jpg225.8 KB · Views: 123 -

CircutBoard (5).jpg236.1 KB · Views: 103

CircutBoard (5).jpg236.1 KB · Views: 103 -

CircutBoard (6).jpg220.5 KB · Views: 104

CircutBoard (6).jpg220.5 KB · Views: 104 -

CircutBoard (7).jpg118.6 KB · Views: 125

CircutBoard (7).jpg118.6 KB · Views: 125 -

CircutBoard (8).jpg209.5 KB · Views: 150

CircutBoard (8).jpg209.5 KB · Views: 150