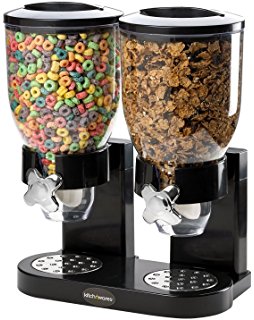

Hey all I am wondering what would be the best items to purchase for me to be able to turn this know (continuous) below:

I'm just needing to know what kind of servo torque I would need in order to turn that without issues of it getting stuck mid-ways.

i spoke to the original creator of that web site project that i linked to and this is what they had to say about the parts that were used:

Are there any servos that have a hole in the middle so that i can slide it over the turning rod and screw down to tighten on it in order to spin it as if you were spinning it yourself with the handle?

Something like this:

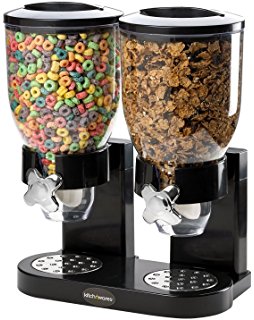

As I mentioned above, I would need the stepper motor to have a continuous rotation in order for it to work with either of these dry food dispensers above.

There is a decent tutorial HERE but really doesn't give much information about how they went about building it and the mentioned Yocto-LatchedRelay seems over priced for something that can be done with just a stepper motor and some logic behind it.

I plan on using a ATMEGA32u4 with this project. I will have a total of 6 of these to control.

The handle/shaft is 2 1/2" long.

The paddle is 3" long

The base (measured from the inside) is 5 7/4"

So any suggestions on what would be best for this type of project would be great and I look forward in hearing them!

I'm just needing to know what kind of servo torque I would need in order to turn that without issues of it getting stuck mid-ways.

i spoke to the original creator of that web site project that i linked to and this is what they had to say about the parts that were used:

We used a small geared Maxon motor (great but expensive hi-tech stuff).

motor

RE-max 13 Ø13 mm, Precious Metal Brushes CLL, 1.2 Watt, with cables

Part-No.: 203888

gear

Planetary Gearhead GP 13 A Ø13 mm, 0.02 - 0.35 Nm, Metal version

Part-No.: 110316

Torque was on the low side: it was enough for regular cornflakes but clearly insufficient for muesli

The problem is not only about finding a motor with enough torque, it's also about finding a motor small enough to fit in the dispenser.

Here are the files. The pulleys were 3D printed,

but the bracket was laser cut in 3mm acrylic glass.

Are there any servos that have a hole in the middle so that i can slide it over the turning rod and screw down to tighten on it in order to spin it as if you were spinning it yourself with the handle?

Something like this:

As I mentioned above, I would need the stepper motor to have a continuous rotation in order for it to work with either of these dry food dispensers above.

There is a decent tutorial HERE but really doesn't give much information about how they went about building it and the mentioned Yocto-LatchedRelay seems over priced for something that can be done with just a stepper motor and some logic behind it.

I plan on using a ATMEGA32u4 with this project. I will have a total of 6 of these to control.

The handle/shaft is 2 1/2" long.

The paddle is 3" long

The base (measured from the inside) is 5 7/4"

So any suggestions on what would be best for this type of project would be great and I look forward in hearing them!