Researchers at Monash University in Australia have announced the development of a new sulfur-lithium battery which they claim has the potential to perform more than four times better than currently available battery products and can power a phone for five continuous days, or allow an electric vehicle to travel more than 1,000km on a single charge.

Lithium-ion batteries, currently used in everything from pacemakers to iPhones and electric vehicles to laptops, could potentially find themselves being replaced by this groundbreaking new energy storage method.

Replacing Lithium-ion with Lithium-sulfur

Theoretically, the lithium-sulfur batteries developed by the team at Monash University are capable of holding up to five times more energy than lithium-ion ones, but until now they have been impractical for use in consumer electronic devices.

This is partly down to the instability of the battery’s cathode, which changes in size by up to 78% each time it completes a charge cycle, quickly degrading the battery and causing it to burn out relatively quickly. However, by using a very flexible cathode, Monash University researchers have discovered that the lithium-sulfur battery can handle the same levels of expansion and contraction without significant degradation. This has led to the researchers’ claim that they have developed the “world’s most efficient” lithium-sulfur battery.

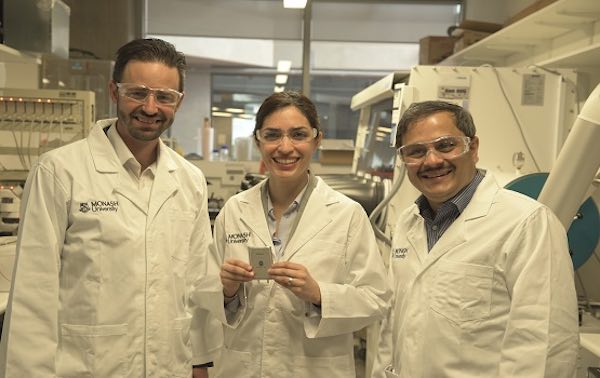

Associate Professor Matthew Hill, Dr. Mahdokht Shaibani, and Professor Mainak Majumder, three researchers from the team at Monash University. Image credit: Monash University.

Dr Mahdokht Shaibani of Monash University’s Department of Mechanical and Electrical Engineering and the leader of the lithium-sulfur battery research project, said: “Lithium-sulfur batteries, which use extremely high-capacity sulfur, can store five-times as much capacity as traditional lithium-ion batteries, and are made from cheap materials that are available worldwide.”

The team’s research, published in Science Advances, could potentially mark a major milestone for the battery industry and could have a lasting impact on everything from consumer electronics to smart cities and beyond.

Shaibani added that the commercialization of the battery could be as many as four years away. However, a patent application for the team’s manufacturing process has already been approved and prototype cells have been developed in Germany. Further testing in cars and solar grids is expected to take place later this year in Australia.

Inspired by 1970s Bridging Architecture

The research team, which last year received more than $2.5 million in funding from government and international industry partners to trial the battery technology, used the same materials used in standard lithium-ion batteries to produce their lithium-sulfur alternative. They then reconfigured the design of sulfur cathodes so that they could accommodate higher stress loads without a dip in capacity or performance.

Inspired by unique bridging architecture first recorded in processing detergent powders in the 1970s, the Monash team engineered a method that created bonds between particles to accommodate stress and deliver an improved level of stability.

Higher performance, lower manufacturing costs, an abundant supply of materials, easy processing, and a reduced environmental footprint when compared to lithium-ion batteries make this new design an attractive prospect for future real-world applications.

"This approach not only favors high-performance metrics and long cycle life, but is also simple and extremely low-cost to manufacture, using water-based processes, and can lead to significant reductions in environmentally hazardous waste," Associate Professor Matthew Hill said.