From drones and video game controllers to forklifts and cranes, joysticks are an effective means of precision control. Development of these tools continues to spur wider and specialized usage in a variety of fields.

Whether you’re a hobbyist building robots, or work in heavy machinery for construction and agriculture, understanding how the technology works at the highest level can lead to fascinating insights.

Industrial Standards are Higher

In heavy industry, precision and accuracy are precursors to speed and efficiency. It’s something farmers, miners, construction workers, and other professionals might realize every time they operate mobile specialized machinery. These details often make the difference between profitability and loss, missed or met deadlines, and safety or danger for the crew.

That’s why you can’t make industrial-grade joysticks the same way you would for a claw machine or a PlayStation controller. These are machines that need to operate for hundreds of thousands of hours over their service lives without any loss in control fidelity.

Joystick Technology: The Power of the Potentiometer

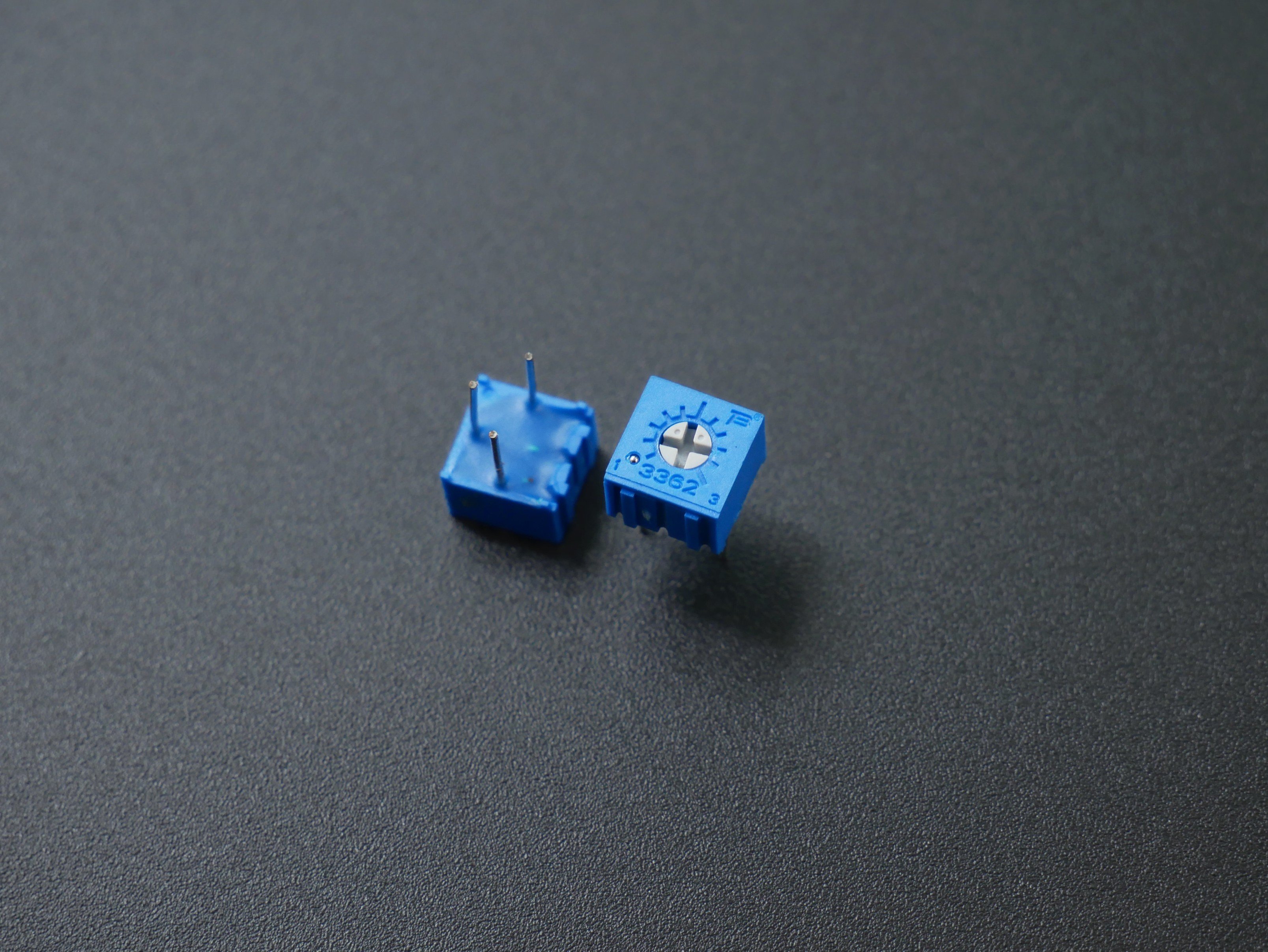

Joysticks need to convert mechanical motion into electrical signals. The part technically responsible for that is called a potentiometer. The word comes from a combination of “potential difference” and “meters.” Potentiometers are devices that react to and are guided (and shielded) by sliding contacts. In a potentiometer, the generated electrical currents are guided between two points to a point of resistance with a wiper; shielded by that sliding outer wall that also serves as a point of friction, the electricity is then harnessed by three terminals that serve different functions to measure and ultimately control the flow of energy output.

So what’s the difference between industrial-grade and consumer-grade joysticks?

Many industrial joysticks use Hall-effect contactless potentiometers, whereas most commercial-grade joysticks use conductive potentiometers. The difference is two metal surfaces contacting (conductive) vs two magnets passing very close to each other (Hall effect).

Hall effect potentiometers are harder to manufacture and are more expensive. But because they don’t physically contact, they provide a much longer functional service life.

Example of a potentiometer, an integral component to any industrial joystick

Other Joystick Types

In terms of industrial grade joysticks, there are many subvarieties of potentiometer that factor in different demands on speed, range of motion, and accuracy, all of which further require customization of materials, including use of LED lights, to create just the right kind of joystick that interfaces best with the rest of the hardware, as well as the machinery itself.

Modern industrial machinery calls for many types of joysticks. Think about the axes of control the joysticks need to operate on, whether they’re hand or thumb joysticks, and the additional buttons and switches their machines need. There are plenty of types out there.

The Human Element

Joysticks need to do more than just work well. They also need to be designed ergonomically and easy to use. These considerations continue to play a major role in their ongoing development. Of central importance is that joystick maneuverability is compatible with “natural” human motions and ease of use, which is why industries that specialize in mechatronics focus on the human side of joysticks as much as they do on the mechanics and computing sides. Because heavy industry is hard work, the technology employed should be as user-friendly as possible, with material and maintenance as important of a factor as ease of use.

The Computer Interface

Once the movement of a joystick is converted into digital signals, they need to be interpreted by the machine or computer.

In terms of circuitry, designers and manufacturers of industrial joysticks also consider the optimal circuitry and materials. Elements that dictate the materials include environmental factors, such as prolonged exposure to extreme temperatures, or complexity of tasks, i.e. routine lifting in a warehouse forklift versus oceanic oil drill maintenance.

Just like with the form of potentiometer used, how advanced any part of the hardware or receiving software will depend on the application. After all, it is possible - but not guaranteed - that the software used in joysticks in a surgeon’s operating room will be vastly different from what is needed on an oil freighter. Factoring in software compatibility is yet another important consideration for any joystick, whether for the hobbyist, gamer, or industrial specialist.

In Practice

There are an increasing number of joysticks in heavy equipment; just as the workforce is only continuing to specialize so are the tools that the workforce is using. With that has come a rise in a myriad of industries that continue to shape the future of end-user-centered technology.

Some of the fields that most rely on customized joysticks include:

- Energy Production

- Medicine

- Construction

- Warehouses

- Agriculture

- Fishing

- Transportation and Ports

- Mining

Careful precision goes into the creation of joysticks for industrial use, as they are the foundation for the fine motor control needed for any project. There are many common materials used, for each part of the joystick, from exterior material to the circuitry to the material used for potentiometers - all with different positive attributes and drawbacks such as durability, heat sensitivity, maintenance concerns, rarity/replaceability, and sustainability.

The future of heavy equipment is literally in your hands. With the increasing amount of customizability, industrial joysticks are taking on more roles than ever before.

Before too long, we’ll likely even start to see more advanced potentiometer technology in the hands of hobbyists. Understanding how they work and the principal technology behind them is the first step. After all, many of the amateur builders and operators of today can become the experts of tomorrow.

Durable joysticks are key to projects that demand precision in many environments