Learn the ins and outs of brushed DC motors and the pros and cons of choosing this type of motor for your project.

If you're working on a project that has a moving part, you'll probably be looking for a motor to make that movement possible. In this series, we explore the most popular types of motors that makers utilize. First up is the brushed DC Motor.

To read up on what types of projects that brushed DC motors work best in, check out the round-up:

What Type of Motor is Best for My Project?

The simplest type of motor (and the most common) is the brushed DC motor. You will find this type of motor all over the place. There is probably one in your phone powering its vibration function. Brushed DC motors are used in just about any moving toy. Cordless drills are powered by brushed DC motors.

Brushed DC motors are used in all kinds of toys, anything with a vibrating motor, and common tools like cordless drills.

How do They Work?

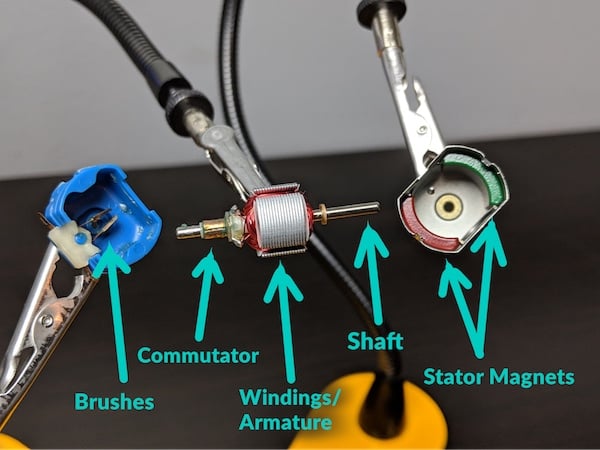

Brushed DC motors are simple devices consisting of only a few parts.

Brushed DC motors are all made up of just a few key parts.

Around the outside of the motor casing are the stator magnets. These are permanent magnets, positive on one side and negative on the other. In the middle of the motor, connected to the motor shaft, are at least three wire windings connected to metal plates called armatures.

On the opposite side of the windings from the motor shaft is the commutator, a pair of metal plates attached to the windings. Finally, the brushes, from which this type of motor gets its name, are located on the side of the motor opposite the motor shaft.

The brushes make physical contact with the commutator. When a DC voltage is applied to the brushes, that voltage is transferred into the commutator which, in turn, powers the windings. This electrical input generates a magnetic field around the armature.

The left side of the armature is pushed away from the left stator magnet, towards the magnet on the right. And the right side of the armature is pushed away from the right magnet, towards the left.

By constantly alternating the polarity of the magnetic field around the armature, the motor shaft is made to continuously rotate.

Brushed DC Motor Pros

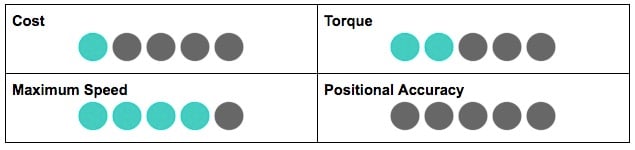

Inexpensive

Brushed DC motors are mass-produced and widely used, making them cheaper than other types of motors.

Easy to Control

Simply apply a DC voltage to make the motor turn. A higher voltage (or higher PWM duty cycle) will make the motor run faster. Reversing the polarity reverses the direction of rotation. Brushed DC motors don’t even need a microcontroller to use, you can make them run just by connecting one to a battery.

High Starting Torque

Brushed DC motors output high torque at low speeds. This is important because this high starting torque allows the motor to get up to speed quickly, even if there is a load on the motor.

Brushed DC Motor Cons

Wears Quickly

Because the brushes physically rub against the commutator as the motor operates, those brushes wear out over time. Therefore, compared with other types of motors, brushed DC motors wear out more rapidly.

Lots of Electrical Noise

Inside a brushed DC motor, electricity arcs between the brushes and the commutator. This causes a lot of electrical noise which is not the best for microcontrollers or sensors working in the same system.

Limited Top Speed

The physical contact between the brushes and the commutator during operation means there is friction between these two parts. Where there is friction there is heat. Brushed DC motors have a limited maximum speed because excessive speed would cause damaging levels of heat.