Hi, I'm doing a little circuit to drive a small vibration motor.

I want to be able to control the voltage that feeds the motor and of course to be able to turn it on and off.

I'm using a microcontroller and digital-to-analog converter.

My first idea was to use an OP amp after the DAC as voltage follower and act as the amplifier for the motor. I quickly found out that OP amps get a little expensive when you're trying to drive larger currents (100mA).

I'm only somewhat familiar with OP amps but would you guys agree that an OP amp is not the way to go here?

So for the clever part I thought of using a simple adjustable LDO linear regulator. I can adjust the voltage and it has an enable pin for on/off. What else can I wish for right?

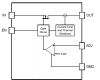

I drew up a little circuit of what I have in mind.

My main question is if this makes sense or if there is a better way to handle this.

My second question is if the protection I use is good. I checked out the motor on the scope and saw voltage swings not only to the negative direction but also the positive (hence the TVS diode).

What do you think? Any comments will be appreciated.

I want to be able to control the voltage that feeds the motor and of course to be able to turn it on and off.

I'm using a microcontroller and digital-to-analog converter.

My first idea was to use an OP amp after the DAC as voltage follower and act as the amplifier for the motor. I quickly found out that OP amps get a little expensive when you're trying to drive larger currents (100mA).

I'm only somewhat familiar with OP amps but would you guys agree that an OP amp is not the way to go here?

So for the clever part I thought of using a simple adjustable LDO linear regulator. I can adjust the voltage and it has an enable pin for on/off. What else can I wish for right?

I drew up a little circuit of what I have in mind.

My main question is if this makes sense or if there is a better way to handle this.

My second question is if the protection I use is good. I checked out the motor on the scope and saw voltage swings not only to the negative direction but also the positive (hence the TVS diode).

What do you think? Any comments will be appreciated.