HarryAussie

- Jan 2, 2024

- 4

- Joined

- Jan 2, 2024

- Messages

- 4

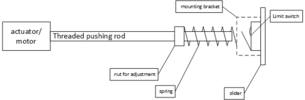

I am looking to set up a motor to drive a linear actuation system (in a lead-screw configuration). It is important that the linear actuation system detects any resistance from a physical object, which in turn will make the motor stop. This obviously protects the motor from stalling, but it also prevents damage to whatever object is being impacted.

My current approach is to measure the current through the motor and set up a current limit such that the motor stops after it reaches a certain high current level. I intend to vary this current limit after some experimentation.

What motor and motor-driver arrangement could work to set this up? Initial searches have proven hard to find motor drivers that measure current (i.e., provide current measurement output signals)! Stepper motors look to be insufficient for this task since their current draw does not fluctuate much during operation under varying loads, so I suspect that servo motors or brushless DC motors are a more suitable choice. I intend to control the system via a Raspberry Pi, and the linear actuation system is small (only 500mm long for the time being).

I am more of a software engineer so apologies if this question is basic to the hardware-savvy folks out there!

My current approach is to measure the current through the motor and set up a current limit such that the motor stops after it reaches a certain high current level. I intend to vary this current limit after some experimentation.

What motor and motor-driver arrangement could work to set this up? Initial searches have proven hard to find motor drivers that measure current (i.e., provide current measurement output signals)! Stepper motors look to be insufficient for this task since their current draw does not fluctuate much during operation under varying loads, so I suspect that servo motors or brushless DC motors are a more suitable choice. I intend to control the system via a Raspberry Pi, and the linear actuation system is small (only 500mm long for the time being).

I am more of a software engineer so apologies if this question is basic to the hardware-savvy folks out there!