ThomsTools

- Jan 26, 2023

- 9

- Joined

- Jan 26, 2023

- Messages

- 9

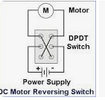

I've got this 1948 1/3 HP craftsman capacitor start motor. Through an access plate you can transpose two wires (reverse the polarity) and the motors start windings will spin the rotor in the opposite direction. I want to achieve this with a DPDT switch. Sometimes however what appears logical is not what it seems. In theory this will work but I would like to know from an expert if this will work as I have laid out.

Thank you.

Thank you.