In this article, we will learn what we need to know about laser engraving and laser cutting

As we are all familiar with the term laser. Many people can easily identify with the word laser. But, laser engraving and laser cutting differ beyond the basic concept of laser definition.

Let's look at some basic definitions of laser engraving and laser cutting. Laser cutting means melting the surface to create a raised mark, while laser engraving creates a deep mark by removing material from the surface. Both methods require high heat and leave permanent marks on the surface.

This permanent marking is necessary due to product discrepancies. Laser engraving and laser cutting have grown in popularity in recent years.

Used everywhere to create logos, serial numbers, VIN, label parts, etc. You can find applications for laser engraving and laser technology in every field.

This article discusses the concepts of laser engraving and laser technology in relation to various factors.

Laser Cutting

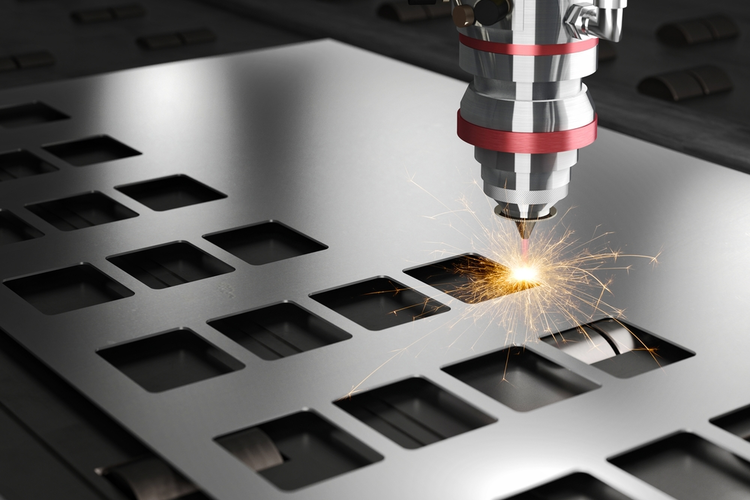

A Laser is Cutting the Surface. Image source: Radshape

Cutting metal using a laser cutter. A laser cutter allows you to design custom shapes using a powerful laser beam.

Laser cutting allows you to cut intricate designs and shapes with great precision.This process makes it easy to cut and shape intricate patterns, regardless of the material.

This process supports a wide variety of materials including metals, plastics, wood, gems, wood, glass and paper.

The laser cutting process offers options such as fusion cutting, oxidation cutting, and scribing.

These processes allow intricate designs to be cut with precision and great precision. All these processes can be used to achieve a high quality edge finish product.

Laser cutting, waterjet cutting, and mechanical cutting methods produce less material contamination and physical damage than other traditional methods, and deliver superior results in terms of accuracy and speed. Waterjet cutting uses high water pressure to shape the object, whereas mechanical cutting uses a cutting tool to deal with laser cutting burrs. Lasers are used to cut and engrave materials.

Resonators, mirrors and laser cutting heads can be seen in the process of laser cutting technology. These are the important parts of the laser processing machine. Laser cutting has the following stages Beam Generation, Beam Focusing, Heating and Melting, Material Ejection, Beam Movement, Gases Used in Laser Cutting.

CO2 is a commonly used gas in laser cutting and serves as the active medium. Initially, Co2 was used for cutting non-metals. Used as a powerful metal cutting tool for further modifications and upgrades.

Neodymium-doped yttrium aluminum garnet (Nd:YAG) and neodymium-doped yttrium orthovanadate (Nd:YVO4) are commonly used for metal cutting.

Crystal laser technology is also used in some large-scale industries, but is not widely used due to its high cost. Fiber lasers are significantly cheaper than crystal lasers. It is therefore considered a better alternative to crystal lasers.

Advantages of Laser Cutting

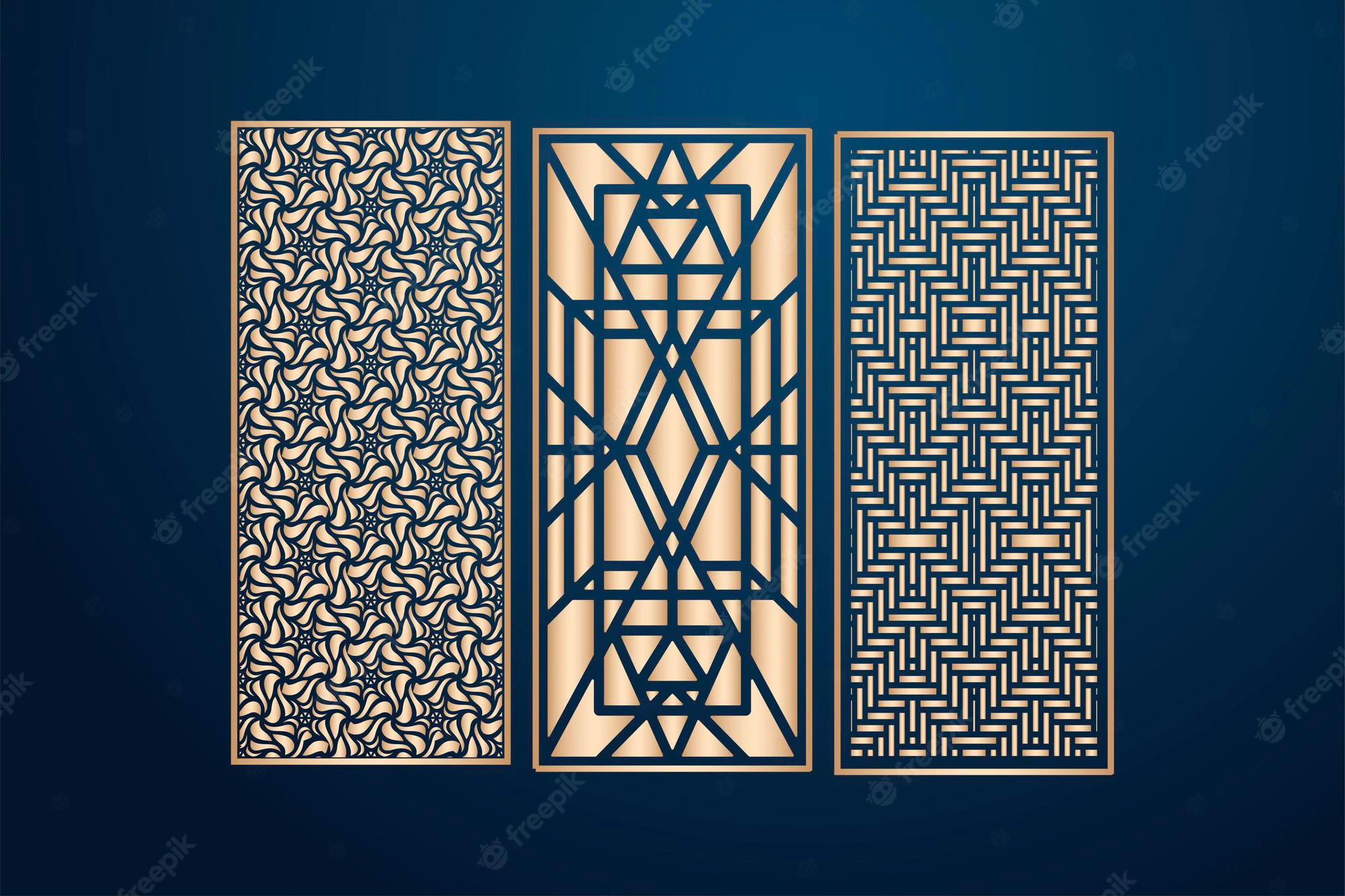

Objects created using laser cutting methods. Image source: Gensun Precision Machining

Using laser cutting technology has many advantages over other traditional cutting methods. It offers

- High Accuracy and Precision

- Excellent Edge Quality

- Narrow Kerf Width

- Less Material Contamination

- Less Maintenance Required

- High Reliability

Laser cutting technology benefits the industry due to its versatility. Complex designs can be cut with ease and precision compared to conventional cutting machines such as water jets and mechanical devices. This technology saves time and leaves no holes in your pockets. The CNC control option also allows you to repeatedly cut out any design.

With this technology, there is no need to manually polish the product as it is highly accurate and requires no further cleaning or finishing. From a safety point of view, laser cutting technology is safe for the operator as this machine has no mechanical parts and the chances of serious injury are very low.

Laser cutting is an environmentally friendly technology as it produces less noise when cutting material and provides an improved working environment.

Disadvantages of Laser Cutting

A laser cutting the metal surface. Image source: RapidDirect

Nothing in the world is 100 percent perfect. Laser cutting also has some disadvantages compared to other conventional methods.

- Conflict in production

- Range of materials required

- Metal hardening

- High electricity and energy consumption

- Higher equipment costs

As we know, laser cutting can cut many types of metal and non-metal with excellent efficiency. But some metals are not suitable for laser cutting technology. The thickness of the material plays an important role in the laser cutting process.

The laser cutting process requires more energy to operate than other conventional methods. For thick metal, more gas pressure and higher laser intensity are required, and the mismatch in alignment takes some time in the manufacturing process.

Laser Pattern

Laser pattern created using laser cutting method. Image source: Freepik

Laser engraving technology is used to write text on metal. With the help of laser engraving, a special image, design or logo can be engraved on a special metal. Laser engraving technology uses a removal technique to cut metal into a specific shape or design.

This process requires a soft copy of the desired design or logo to be downloaded to your computer. Then, according to a specific example of the technique, the device takes place and the engraving process begins. A superheated laser beam passes through the material to create the design by burning or vaporizing the material.

The laser engraving process uses two engraving technologies: linear engraving and surface engraving. Line engraving technology uses vector graphics to print on materials. Instead, the surface pattern burns and evaporates the material and creates a 3D effect on the surface.

Types of Machines and Materials