Learn about torque, how it applies to motors, and why torque ratings are so important to consider in your projects.

In basic physics, you are probably accustomed to thinking about linear forces, for example, the force of gravity pulling objects straight down or the force you exert on a shopping cart while pushing it. Torque is similar to linear forces, but where linear forces cause an object to move in a straight line, torque causes objects to rotate.

If you've ever opened a door, you have an intuitive understanding of torque. When you are opening a door, you exert a force on the side of the door farthest from the hinge. Because the door is rigid, your force acting at a distance from the center of rotation of the door (the hinge), causes the door to rotate and open. You could open the door by pushing the side of the door closest to the hinge, however, as you know, this would require much more force to get the door to open. This is because you are generating less torque by reducing the distance between you and the center of rotation of the door.

Torque is calculated by multiplying a linear force and the distance that force is exerted from the center of rotation. The classic example of torque is a wrench being used on a nut. If you have a wrench that is 20 cm long, and you push down on the wrench with 2 kg of force, the torque on the nut is (20 cm x 2 kg =) 40 kgᐧcm.

A classic example of torque is seen when you use a wrench to affix a nut.

When we look at motors, the calculation for torque is the same—a force multiplied by a distance.

The only difference is that, unlike with a wrench where a force is applied to the arm, with a motor, torque is directly applied at the center of rotation, producing a linear force at the end of the arm. When thinking about a motor’s torque, you could imagine the motor using an arm to lift a weight. The maximum weight the motor is able to lift will be its maximum torque.

In motors, torque is applied at the center of rotation to produce a linear force.

Motors that are designed to deliver greater torque are able to exert greater forces on other objects.

Why is Torque Important?

Torque, and especially designing systems with motors that deliver the correct amount of torque, is incredibly important across a huge range of different applications.

Let’s say you are building a robot. If you want to build a larger robot, or a robot capable of lifting heavier objects, you will need stronger motors, able to deliver more torque, to get the robot to move. Take a look at the video below, which shows what happens if you build a robot without taking the time to calculate how much torque the motors will need to deliver.

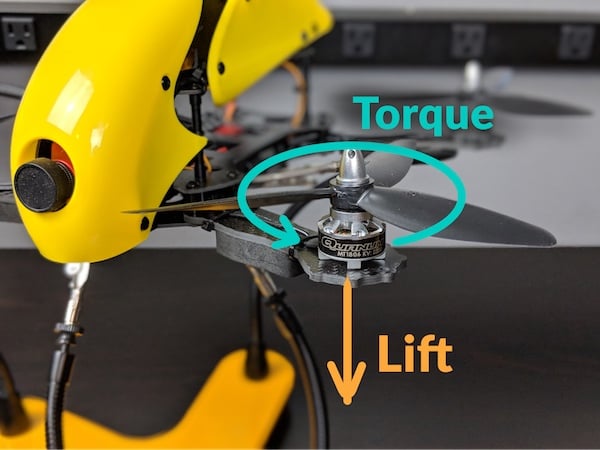

For aircraft, the torque delivered by the motors directly determines the maximum lift the propellers can generate.

If you are building a car and you want it to accelerate faster, you will require more torque from the motors - in a vehicle, the force propelling it forward is (roughly) the engine's torque divided by the radius of the tires.

Electric cars, like the Tesla Model S, are renowned for their rapid acceleration because their electric motors generate a huge amount of torque. This torque translates directly to a large force exerted by the tires on the road's surface. As taught in basic physics, exerting a larger force on an object will cause it to accelerate more quickly.

What Factors Affect a Motor's Torque Rating

There are three different, but interconnected, limiting reagents when it comes to a motor's maximum torque rating.

The Mechanical Properties of the Materials

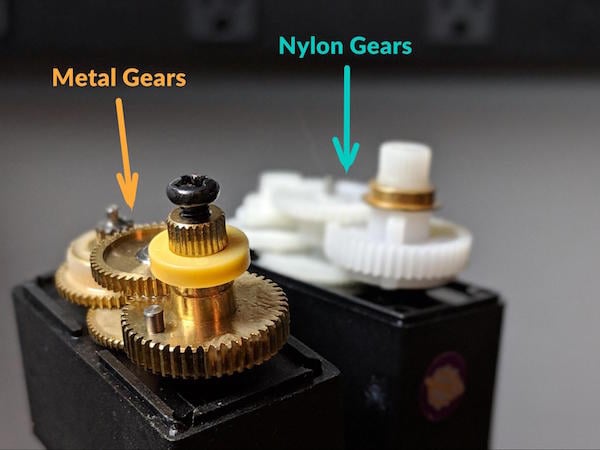

The first is the mechanical properties of the materials involved. Different servo models are a good example of this design consideration.

Cheaper, lower torque servos use plastic gears, usually made from nylon. Plastic gears are inexpensive to produce, making servos with nylon gears cheaper to manufacture and cheaper to buy. Nylon gears are also lightweight compared to metal, which is an important consideration for robotics or aircraft. However, if too much torque is exerted on these nylon gears, they will break.

Servos with higher torque ratings have metal gears so they can deliver higher torque without breaking. The materials used in a motor's construction play a huge role in determining how much torque the motor is able to deliver.

Motors are made with a variety of materials, but generally, those made with metal have a higher torque rating than those made of nylon or another plastic.

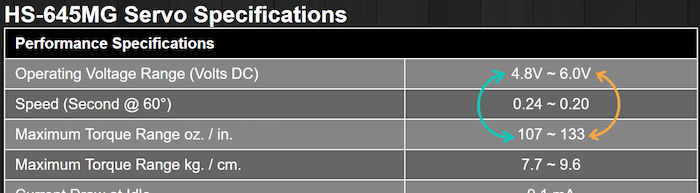

The Motor’s Maximum Voltage

The second factor affecting a motor's maximum torque is the maximum voltage the motor is designed to accept. If you take a look at any servo specs page, you will find different torque ratings for different voltages. Higher voltages give the motor more power to deliver higher torque. However, the motor, and it's driving circuitry, can only accept so much voltage before overheating and burning out. The maximum voltage the motor can accept without failing factors into its maximum torque rating.

A motor's maximum voltage is given in the specs provided by manufacturers.

The Motor’s Heat Generation

This brings us to the final limiting factor for a motor's maximum torque. As motors work they generate waste heat. The harder the motor works, the more heat it generates.

For most motors used in hobby projects, from DC motors, to servos, to stepper motors, that waste heat is simply radiated into the air. There is no active cooling like you would find on, for example, an electric car. Therefore, a motor is limited by how much torque (and also speed) it can generate without risking thermal failure.

Measure a Motor's Torque on Your Own

We've covered why staying within a motor's maximum torque is so important. So what do you do if you think your motor isn't up to the challenge? Have no fear! We have a project to show you how to measure the torque of a servo motor.

Double-checking the torque of your servo motor before you incorporate it into your project will help save you from the frustration of building and rebuilding!