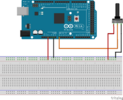

I'm using an Ardunio Mega board and a pot to control a 180 servo. The problem I am experiencing is that the pin read on the pot jumps around from 0 to 600 or so and I don't get a smooth 0 to 1024 range. I don't know if this is because the pot I am using is a cheap hobby pot and I need to higher quality pot or if it's something in my Ardunio code, or maybe my wiring is at fault?

Any comments appreciated. Thank you.

Any comments appreciated. Thank you.