Notice - for comments or questions please e-mail me. instead of posting a reply here.;

by keeping postings to a minimum this project will be more readable and easier

to follow along.

relevant messages from viewers will be mentioned here. with preference to those

doing an identical or similar coding and circuitry testing.

my goal is to provide everything that goes into replacing the factory analog

ignition on a 1-stroke motorcycle with a digital replacement.

such that you will be set to adapt the code and circuit to your engine

reach me at [email protected]

7-17-16

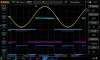

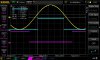

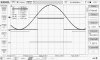

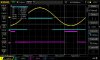

the circuit to convert the -71 deg sine lobe is shown today. its the first , positive V lobe,

the -V lobe is the -10 deg signal. the sine wave from a function generator is being used to

simulate the flywheel sensor signal . that signal works fine for testing our ADC circuits.

but wont work for the uC that is measuring the time between the + and - sine lobes.

( see the scope image on the july 11 posting )

and for a first go-around this -71 deg ADC circuit is working well.

later it will be placed in parallel with the -10 deg ADC circuit. and then we'll see how well they

play together. we need both their output pulse signals for the uC.

and then the fire-pulse out of the uC along

with the -10 deg pulse will be the 2 inputs to a TTL 7432 OR - gate. the output of which goes to the CDI circuit board to make it fire off a spark

all that will be coming up next.

and a preview ... the ADC circuits will be on their own PC board. and will follow the 2014

CDI circuit design example and use an opto-coupler to connect to the CDI circuit board.

among other things doing it this way will modular-ize the ignition system so that the same ADC board could then be connected to a 2'd CDI board. ex. one based on the UC3845 chip .

another bonus is isolating the two boards so that they do not share a common ground.

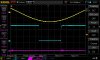

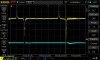

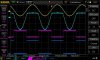

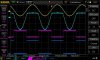

a few things to notice on the scope screen image ...

0. i messed up with the sine wave amplitude. it was suppose to be +/- 3V

and looks to be closer to +/- 4 . and possibly a little asymmetry

1. the CH 2 signal flattens out at about 1.4 V . or 2 diode V-drops . the 4148

and the Q's b-e jct combine to act like a 2*(0.7) = 1.4 zener diode clipper

2. the CH 3 pulse edges are visible and after the 7414 works them over

they are too fast to appear on the screen with the sweep rate of .010 sec/div.

this is graphic evidence of a Schmitt trigger in action

3. even tho the input sine wave goes to -4V there is no evidence in CH 3 or 4 that

it pulls those pulse signals below ground. thus no protection measures are needed

for the 7414 input pin

by keeping postings to a minimum this project will be more readable and easier

to follow along.

relevant messages from viewers will be mentioned here. with preference to those

doing an identical or similar coding and circuitry testing.

my goal is to provide everything that goes into replacing the factory analog

ignition on a 1-stroke motorcycle with a digital replacement.

such that you will be set to adapt the code and circuit to your engine

reach me at [email protected]

7-17-16

the circuit to convert the -71 deg sine lobe is shown today. its the first , positive V lobe,

the -V lobe is the -10 deg signal. the sine wave from a function generator is being used to

simulate the flywheel sensor signal . that signal works fine for testing our ADC circuits.

but wont work for the uC that is measuring the time between the + and - sine lobes.

( see the scope image on the july 11 posting )

and for a first go-around this -71 deg ADC circuit is working well.

later it will be placed in parallel with the -10 deg ADC circuit. and then we'll see how well they

play together. we need both their output pulse signals for the uC.

and then the fire-pulse out of the uC along

with the -10 deg pulse will be the 2 inputs to a TTL 7432 OR - gate. the output of which goes to the CDI circuit board to make it fire off a spark

all that will be coming up next.

and a preview ... the ADC circuits will be on their own PC board. and will follow the 2014

CDI circuit design example and use an opto-coupler to connect to the CDI circuit board.

among other things doing it this way will modular-ize the ignition system so that the same ADC board could then be connected to a 2'd CDI board. ex. one based on the UC3845 chip .

another bonus is isolating the two boards so that they do not share a common ground.

a few things to notice on the scope screen image ...

0. i messed up with the sine wave amplitude. it was suppose to be +/- 3V

and looks to be closer to +/- 4 . and possibly a little asymmetry

1. the CH 2 signal flattens out at about 1.4 V . or 2 diode V-drops . the 4148

and the Q's b-e jct combine to act like a 2*(0.7) = 1.4 zener diode clipper

2. the CH 3 pulse edges are visible and after the 7414 works them over

they are too fast to appear on the screen with the sweep rate of .010 sec/div.

this is graphic evidence of a Schmitt trigger in action

3. even tho the input sine wave goes to -4V there is no evidence in CH 3 or 4 that

it pulls those pulse signals below ground. thus no protection measures are needed

for the 7414 input pin

Last edited: