Hello Guys. I am working on a fuel pump project. The fuel pump works like a solenoid. It needs to be switched on and off frequently in order to pump the fuel. I plan to use an Arduino to handle the switching frequency, but I am having trouble coming up with a switch device. here is the low down.

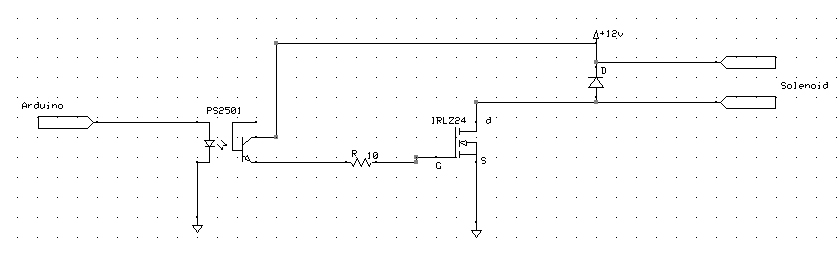

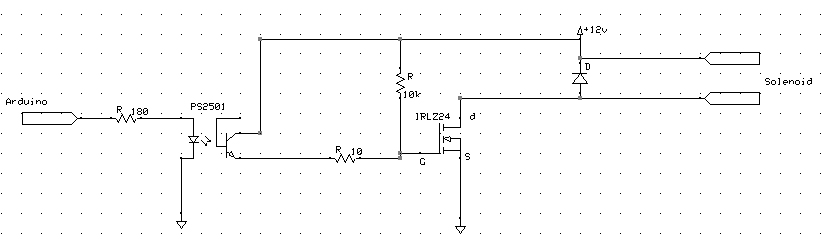

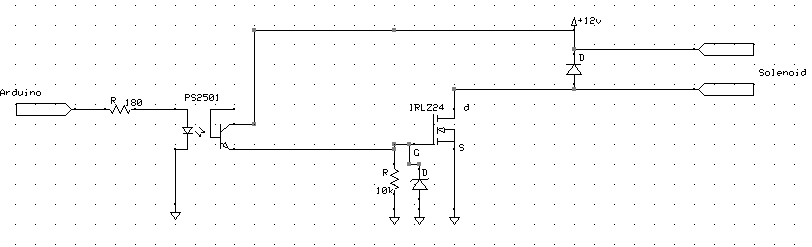

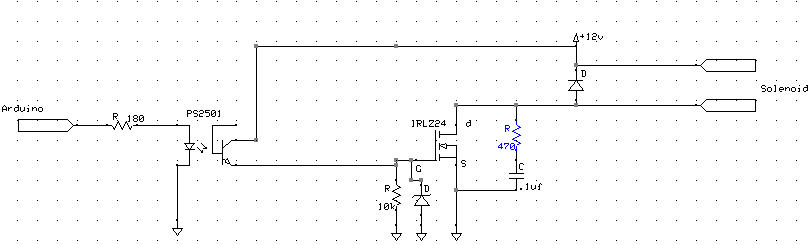

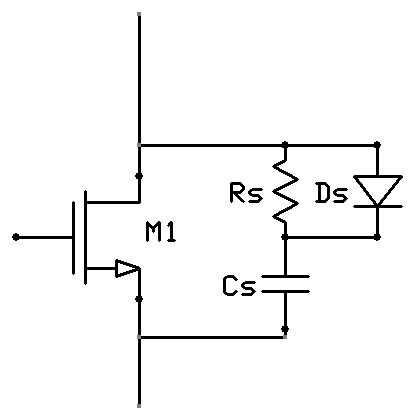

The pump runs off of 12V and uses between 1.5 and 2A when powered. The normal 3906 transistor just won't cut it. I thought about a mechanical relay, but am afraid it won't be able to switch fast enough. I was looking at this circuit:

Again the problem is the transistor can't handle the current I need to supply. I am hoping someone will have some suggestions. Maybe a mechanical relay will be able to do it. I am not sure. Just hoping I could get some insight.

Thanks in advance..

The pump runs off of 12V and uses between 1.5 and 2A when powered. The normal 3906 transistor just won't cut it. I thought about a mechanical relay, but am afraid it won't be able to switch fast enough. I was looking at this circuit:

Again the problem is the transistor can't handle the current I need to supply. I am hoping someone will have some suggestions. Maybe a mechanical relay will be able to do it. I am not sure. Just hoping I could get some insight.

Thanks in advance..