lostintranslation

- Nov 6, 2013

- 26

- Joined

- Nov 6, 2013

- Messages

- 26

I have this digital volt meter and it works,

http://www.ebay.com/itm/221293228404?ssPageName=STRK:MEWNX:IT&_trksid=p3984.m1439.l2649

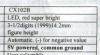

but I needed to get one with higher impedance, so I got this one. my problem is figuring out if it will even work and how to wire it into the circuit.

http://www.jameco.com/webapp/wcs/stores/servlet/Product_10001_10001_2144606_-1

http://www.ebay.com/itm/221293228404?ssPageName=STRK:MEWNX:IT&_trksid=p3984.m1439.l2649

but I needed to get one with higher impedance, so I got this one. my problem is figuring out if it will even work and how to wire it into the circuit.

http://www.jameco.com/webapp/wcs/stores/servlet/Product_10001_10001_2144606_-1